3 min read

Streamlining Biologic Manufacturing with Expedited Process Transfer and Downstream Optimization

Nick McDonald July 3, 2024 at 7:24 AM

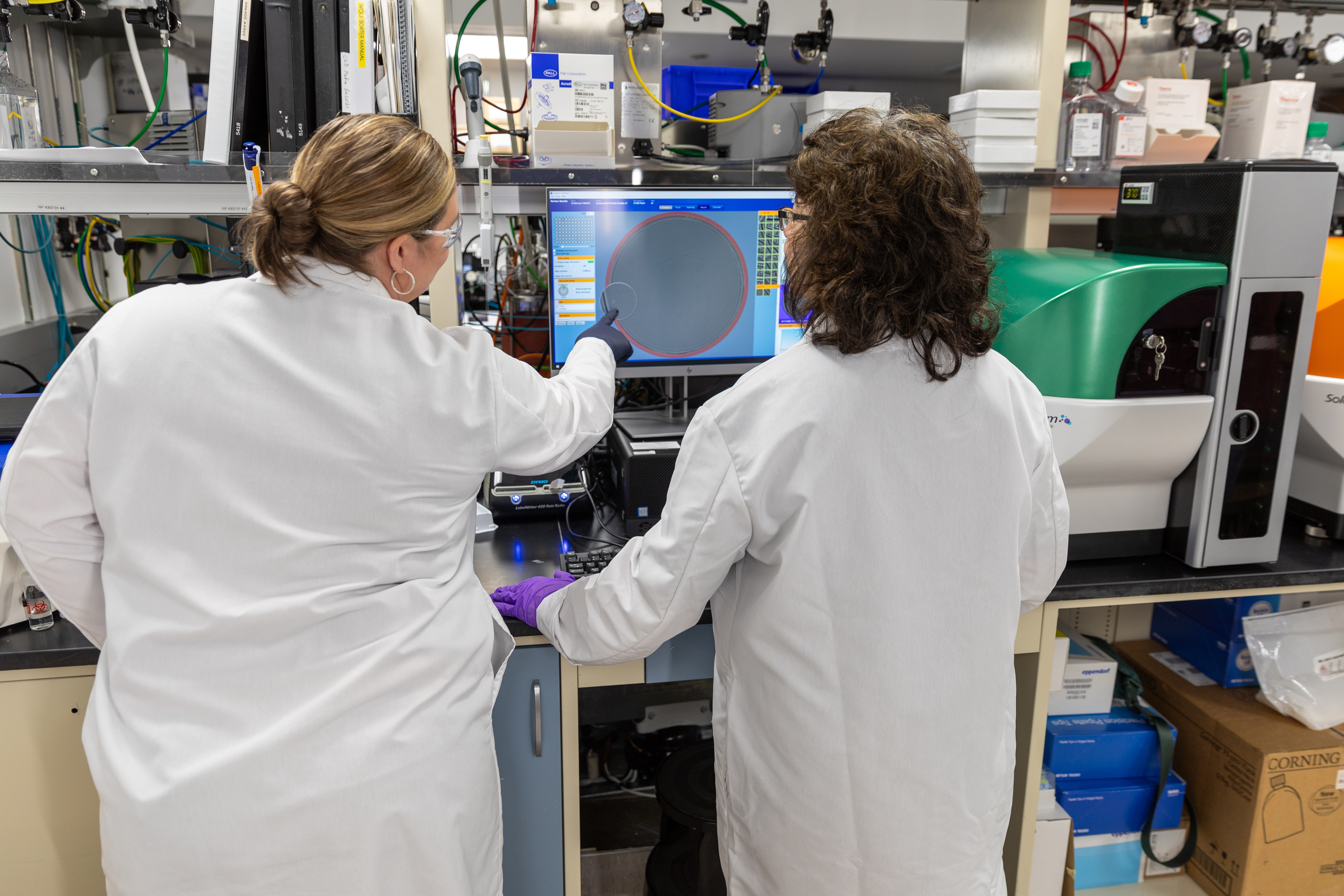

Bringing a biologic to market by overcoming GMP manufacturing obstacles using flexibility and experience.

It’s a rare event when a small scale biologic production process seamlessly translates into full-scale production without the need for optimizations. Most biological products are first produced in the laboratory as small research and development batches, designed for rapid proof-of-principle confirmation. Typically, bench-scale production methods have not been designed to translate into scalable GMP manufacturing processes, so when production methods are transferred to a contract development manufacturing organization (CDMO) for scale up, all process steps must be evaluated—for efficiency, compatibility with manufacturing platforms, and quality control processes to start—and usually require optimization. Adding complexity to manufacturing are the demanding timelines facing biologics producers in a highly competitive market.

However, with careful experimental planning and execution by an experienced CDMO team, processing issues that threaten to limit product yield, purity, and on-time delivery can be successfully mitigated. Here, we provide just a few examples of how the AGC Biologics Downstream Development Teams overcome titration and precipitation challenges, and tight timelines, to deliver high quality biologics using expedited process transfer and creative problem-solving.

Meeting tight timelines for process transfer

To offer the fastest path to full-scale biologic production, the AGC Biologics Downstream Development Teams can fast-track scale-up, with expedited process evaluation and transfer. Small model qualification (SMQ), process characterization (PC), and process performance qualification (PPQ) can prove to be the first hurdles to timely production. Taken together, these confirmation and characterization requirements involve 10 different studies, most of which are typically performed sequentially, with design of each study being informed by the results of the previous one. Yet, through careful design, targeted use of information from small-scale studies, and coordination within the team, these studies can be performed concurrently, shaving months off the timeline.

Problem-solving: titration optimization

For R&D production batches, laboratory researchers rarely need to think about choice of titrant when adjusting the pH of a solution because there are no process restrictions on volume addition, as long as the final product is in the target range. If target pH overshoot is a concern, the researcher typically reduces the volume of titrant added and repeats that addition as many times as necessary.

However, this practice can pose problems during GMP biologics manufacturing. For example, the use of a weak acid to adjust pH to a target range at full-scale production can lead to the addition of large volumes of titrant to the final product, and it can be difficult to determine how many highly technical titrant addition steps will be required during routine manufacturing. With variable measuring and mixing times, production batches could sit at low or intermediate pH for variable lengths of time, resulting in a deviation from approved manufacturing procedures and potentially compromising product quality and yield.

In addition, to protect the sterility of biologic drug substance or drug product, titrant volumes must be pre-determined and aseptically pumped into solution in the fewest additions possible—ideally limited to two or three additions. A titrant that does not robustly conform to expected, calculable performance should be replaced prior to manufacturing. AGC’s Downstream Development Team understands these issues and can identify titration challenges early during the process qualification phase and optimize titrant choice for reproducible production processes that result in consistent product quality and yield.

Overcoming precipitation challenges

Precipitation during biologics manufacturing is another concern that must be identified and addressed prior to full-scale manufacturing. Many biologics require a low pH neutralization step to inactivate viral or cellular components. Following neutralization, the pH of the batch is raised which can induce the formation of host cell impurity precipitates. These precipitates must then be separated from the product. For R&D batches, it may be sufficient to allow precipitate to settle within the production vessel or centrifuge the vessel, and then remove the supernate using sterile in-line filtration. However, settling and centrifugation are not practical for continuous bioprocessing methods and in-line filters can quickly clog leaving behind valuable product.

AGC’s Downstream Development Team understands the factors that contribute to precipitation and can implement processes that minimize product loss. By carefully controlling the timing and rate of pH adjustments, precipitation and protein aggregation can be minimized. Additionally, selection of a purification filter type that is chemically compatible with the product and optimal for the manufacturing process can contribute to higher uniformity between manufacturing lots. For example, replacing an in-line filter with a depth filter may extend filter life and provide a more controllable separation process that results in faster processing, lower costs, and maximum product yield.

Benefits of working with a CDMO

Any biologic ready for scale-up can benefit from a thorough evaluation of developed manufacturing processes by an experienced CDMO partner. With decades of experience and a deep understanding of robust manufacturing processes, the AGC Biologics Downstream Development Teams can proactively identify potential manufacturing problems and resolve them in the early stages of process transfer. The optimization of production processes can result in improved efficiency, higher product yields, cost savings, and on-time delivery of a high-quality biologic.