Process Development

Our expertise spans biologics using mammalian and microbial systems, cell therapies, and viral vectors

Our scientists apply decades of expertise to ensure the most effective processes for manufacturing your product at a pilot, clinical and commercial scale. Our broad knowledge of cGMP manufacturing enables us to successfully transfer existing processes into our facility or develop a new, innovative process when needed to meet your program objectives.

Process Development for Biologics

At AGC Biologics we have developed over 200 mammalian, bacteria and yeast-based processes, giving us the insight necessary to identify and optimize process parameters that are critical for achieving a high-quality, cost-effective manufacturing process.

Developing an efficient, scalable, validated and cost-effective manufacturing process is essential for success in today’s competitive biologics markets. Whether you need assistance developing a de novo process, improving existing processes, or preparing to manufacture your product, you will benefit from our expertise.

Process Development for Advanced Therapies

Our cell therapy process development capabilities include a proprietary production platform for T-cells and HSCs transduction, process characterization studies, cell biology analytical testing and development, and more.

AGC Biologics cellular biology laboratories have the ability to support important processes like CD34+ and T-cells transduction, as well as T-cell immunomagnetic selection, culturing, and transduction by viral vector.

Our viral vector process development capabilities also utilize proprietary platforms (adhesion and suspension) for adeno-associated viral vectors (AAV), lentiviral vectors (LVV), and retroviral vectors (RV). The AGC Biologics viral vector process development services include process characterization studies, verification batches, and cell banking.

For both cell therapy and viral vectors, we offer pilot batches and full-scale batches for new clients prior to transfer in GMP.

Upstream Process Development

Each step in an upstream process impacts the quality, purity, and quantity of the manufactured protein, cell therapy or virtual vector product. At AGC Biologics, we have teams with the insight necessary to identify and optimize upstream parameters that are critical for achieving a high-quality, cost-effective biomanufacturing process.

Our process transfer platform is well-substantiated and designed to scale-up directly, from bench-scale to final manufacturing scale, accelerating your development timelines.

In addition, our development team is experienced with fast and effective technology transfer to establish proven processes. This ensures that you receive a seamless route to scale-up and cGMP manufacture.

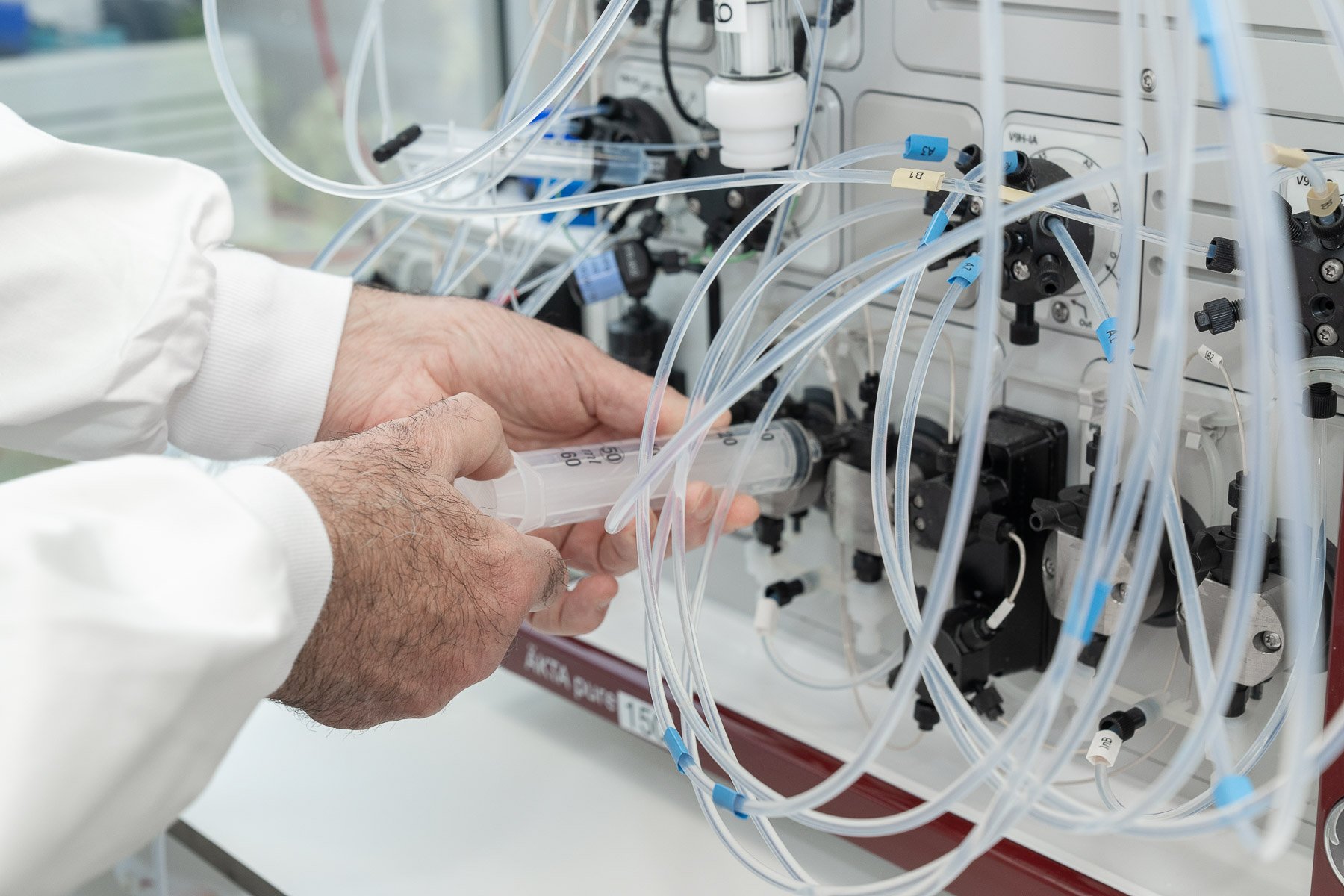

Downstream Process Development

Downstream processes for monoclonal antibodies, recombinant proteins, complex glycoproteins, bacteria and yeast, cell therapies, and viral vectors.

We have established downstream platforms that allow us to move quickly into a product’s manufacturing phase. Our experience also enables us to develop more customized and innovative solutions to meet our customers’ evolving needs.

We optimize our downstream processes to remove impurities and increase yields with minimal steps and optimal recovery, leading to more cost-efficient manufacturing.

Our downstream process development and analytical teams are fully integrated to ensure we achieve the product quality attributes. One example includes our tailoring of processes to remove undesired product variants, such as under-sialylated molecules, aggregates and oxidation variants.

AGC Biologics has partnered with Gore to improve downstream purification

Visit our landing page to learn more or read the press release here.

Systems analysis: Eliminating Downstream Bottlenecks

View this article to understand how AGC Biologics and Gore are working together to reduce expenses, speed up timelines, preserve materials, and optimize facility use.

Download