- Case Study -

At-Scale LVV Production

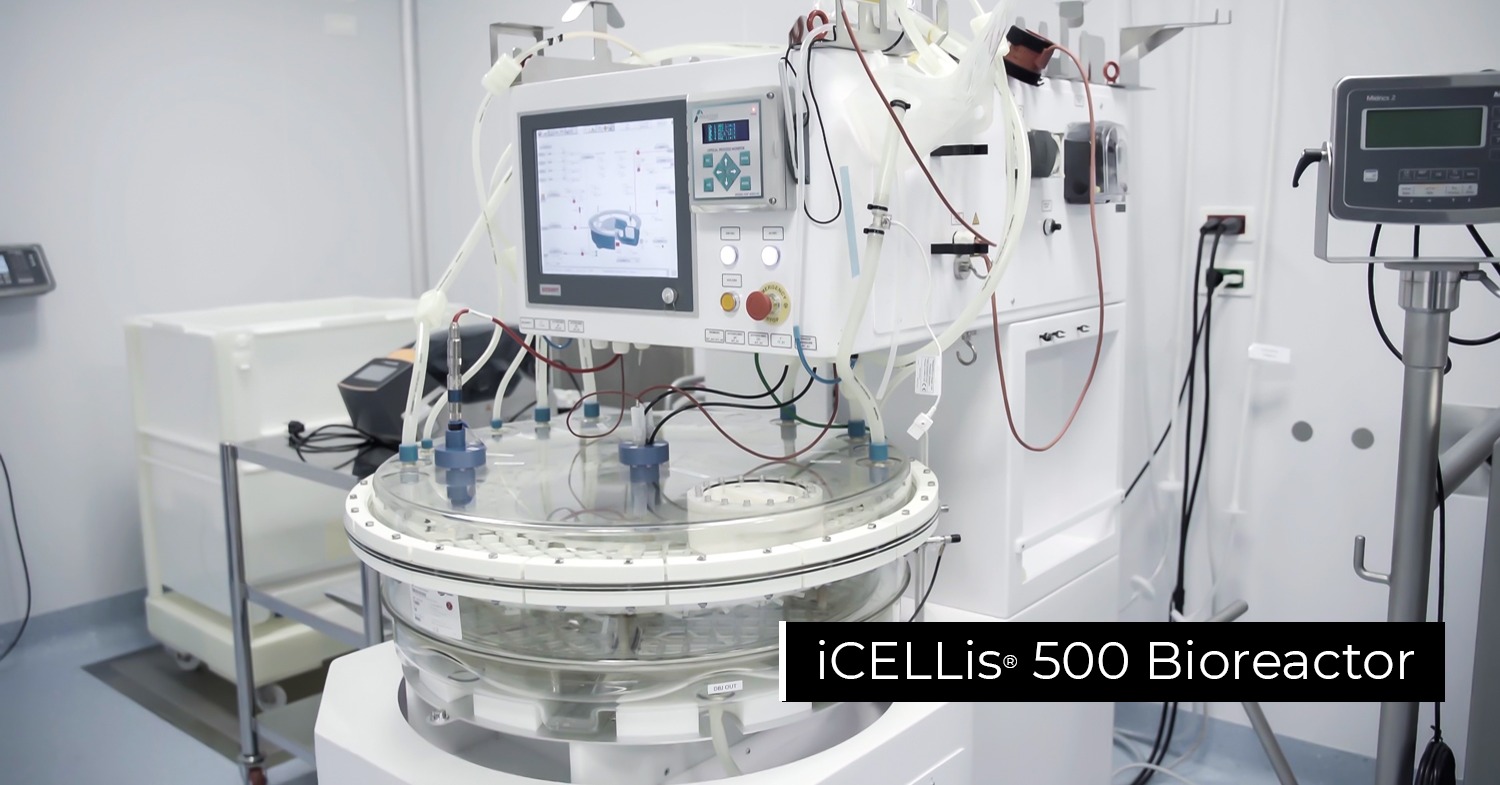

Scaling From Cell Factory™ Systems to an iCELLis® 500 Bioreactor without Affecting Critical Quality Attributes

The Challenge

Evolving from the well-established GMP 48L Nunc™ Cell Factory™ (CF) process, identify an effective, replicable, and large-scale lentiviral vector (LVV) manufacturing process to meet the growing manufacturing demand – especially for market application – without affecting critical quality attributes.

The AGC Biologics Solution

The upstream process was developed by leveraging the scaled-down iCELLis® Nano system where key process parameters were screened in order to increase productivity, producing a bulk vector with a consistently low contaminant profile. Data obtained on the full-scale iCELLis® 500 system confirmed full scalability and equivalent performance of the well-established CF process.

The upstream process was developed by leveraging the scaled-down iCELLis® Nano system where key process parameters were screened in order to increase productivity, producing a bulk vector with a consistently low contaminant profile. Data obtained on the full-scale iCELLis® 500 system confirmed full scalability and equivalent performance of the well-established CF process.

The downstream process was designed to remove main product and process related contaminants (Host Cell Proteins, Host Cell DNA, plasmid DNA, and BSA), thus maintaining vector, and consists of an anion exchange chromatography step that captures and concentrates the vector, enabling 80% recovery while removing HCPs, DNA and BSA. Eluted vector is then concentrated and diafiltered with TFF using hollow fibers. With this step, the vector is further concentrated with 80% recovery, and additional contaminant removal is achieved. The vector is then 0.2µ sterile filtrated and filled in vials.

Through our testing and optimization, we’ve gathered data that shows a total process recovery of approximately 30%.

The Results

Final purified vector data shows a similar impurity profile as the established 48L CF process. The new process has already been successfully implemented for the manufacture of different vectors with different Gene of Interest (GoI).

With the ability to produce a quantity of 4-5x vector TU without a loss in quality, the iCELLis® 500 platform offers a scalable and cost-effective solution with regard to the number of patients treated versus the cost of production and quality control. Moreover, the possibility to leverage the analytical platform already in use for the GMP 48L CF process accelerates the transition from development to GMP clinical and commercial production with reduced comparability exercises.