- Case Study -

Improving Turnaround Time and Efficiency in Microbial Identification

Optimizing Microbial ID for Enhanced Contamination Control: Implementation of MALDI-TOF MS and Axcess

The Challenge

Microbial identification is crucial for contamination control and response in biopharmaceutical manufacturing facilities. Knowing the specific identity of a contaminant enables targeted and rapid remediation, maintaining control of the manufacturing process. Traditional microbial identification methods can be time-consuming, hindering a swift response to contamination events. Delays in identification can extend deviation closure times, negatively impacting site KPIs and delaying lot disposition for clients, which in turn delays payments. Furthermore, root cause analysis is more effective when performed closer to the event, and corrective actions may be misdirected if the organism identification is unknown.

The AGC Biologics Solution

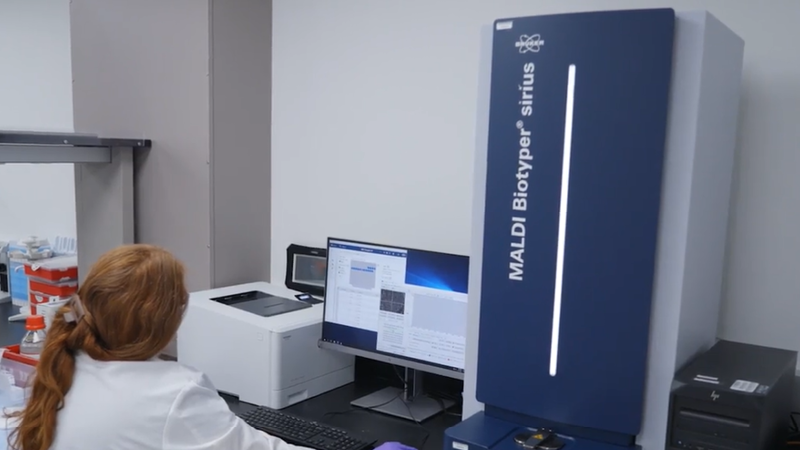

AGC Biologics addressed these challenges by implementing the Bruker MALDI-TOF (Matrix-Assisted Laser Desorption Ionization-Time of Flight) mass spectrometry system, paired with the Axcess Organism Database from Accugenix and Charles River. MALDI-TOF utilizes mass spectrometry to generate a unique spectral fingerprint of a microorganism, which is then compared to a database for rapid identification. This technology provides results in seconds, a significant improvement over traditional methods that can take days or only offer limited results. The implementation of MALDI-TOF and the Axcess database has streamlined the microbial identification process at AGC Biologics.

The Results

Accelerated Microbial Identification and Enhanced Efficiency

The implementation of the MALDI-TOF system has significantly improved turnaround times for microbial identification at AGC Biologics.

- Reduced Turnaround Times: The average time from final fill to organism identification has decreased from 28 days to 16 days. After subtracting incubation time, the average wait for identification has been reduced by over 50%, from 19 days to 7 days. This allows deviation investigations to proceed more quickly.

- Improved Agility in Contamination Response: The rapid identification provided by MALDI-TOF improves agility in responding to high-criticality contaminations in both upstream and downstream processes. System remediation can be initiated and completed before the next batch, preventing potential batch loss.

- Cost Savings: Performing microbial identification in-house with MALDI-TOF is more cost-effective than shipping samples to off-site vendors.

- Enhanced Root Cause Analysis and Corrective Actions:More rapid identification enables more successful root cause analysis and allows for corrective and preventative actions to be implemented based on accurate information.

The implementation of the Bruker MALDI-TOF system has significantly improved microbial identification processes at AGC Biologics. It has reduced turnaround times, enhanced responsiveness to contamination events, and provided cost savings. This improvement enables more effective contamination control strategies, contributing to overall process productivity, quality, and patient safety.